Business Process Continuity for Efficient Company Operations

Today’s market situation, characterized by globalization and frequent economic crisis, is rather ruthless – Latvian companies and producers are facing competition from all around the world. In order to maintain the position of the preferred choice of the consumer, we all are on the constant look-out for new promising methods to deliver higher levels of efficiency. Popularity of Lean, TOC and Six Sigma continues to grow which is great; however, in my opinion, every company should also regularly revise and improve their internal risk management and closely associated business process continuity procedures. By developing and implementing viable business continuity and disaster recovery plans which, in general, do not require a large financial investment, Your Company will not only enjoy higher productivity rates but also see the added value of the business increase significantly.

BCP and DRP - An Integrated and Complex Approach to Risk Management

You may possibly ask, how do these plans differ from each another? The main goal of a business continuity plan (BCP) is to continuously monitor business infrastructure and carry out preventive activities in order to eliminate any potential downtimes and minimize their negative impact on business, if they do occur. Disaster recovery plan (DRP), on the other hand, sets out specific guidelines for a particular sequence of actions to be taken and communication needed in order to restore full business functionality as soon as possible. In my opinion, both of them supplement each other really well and create a complex and thorough set of activities and procedures. Those taken together are able to bring the impact of various business performance risks down to a minimum, allowing Your Company to deliver goods or provide services within the agreed scope and time frame.

Focus on Information Systems

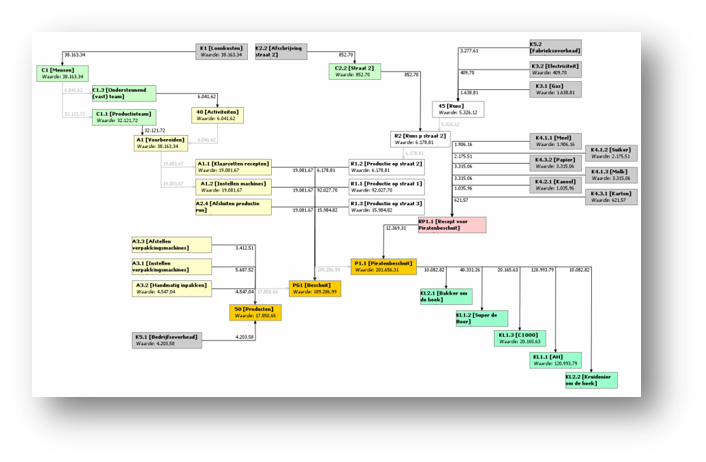

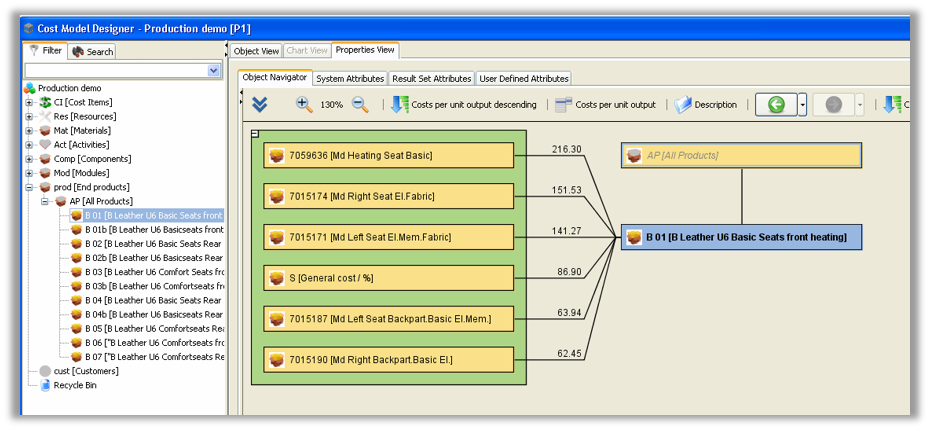

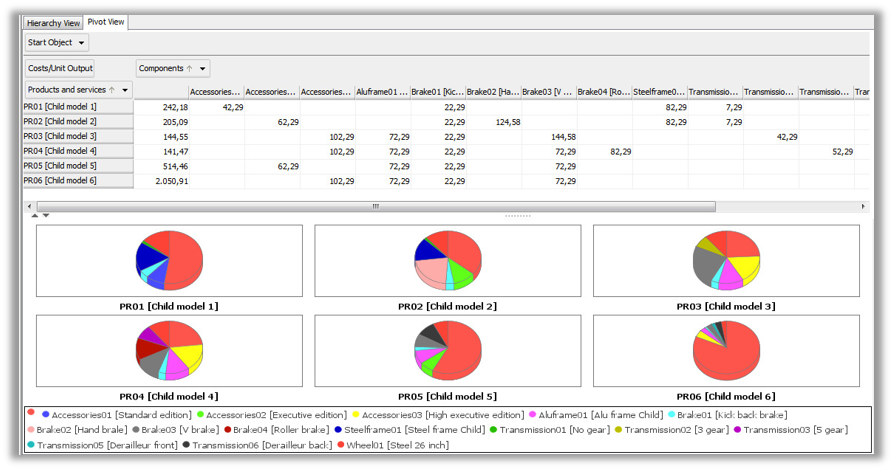

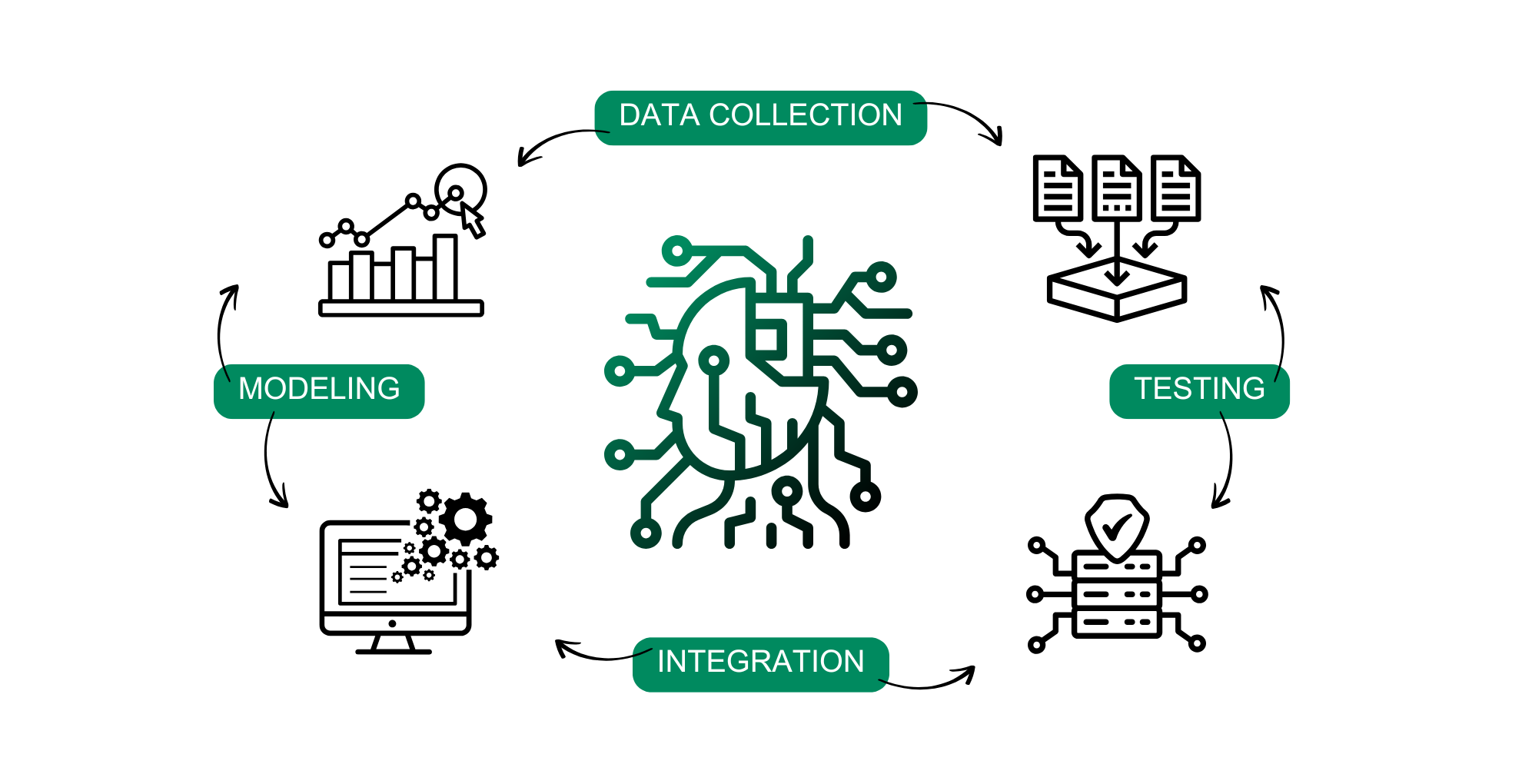

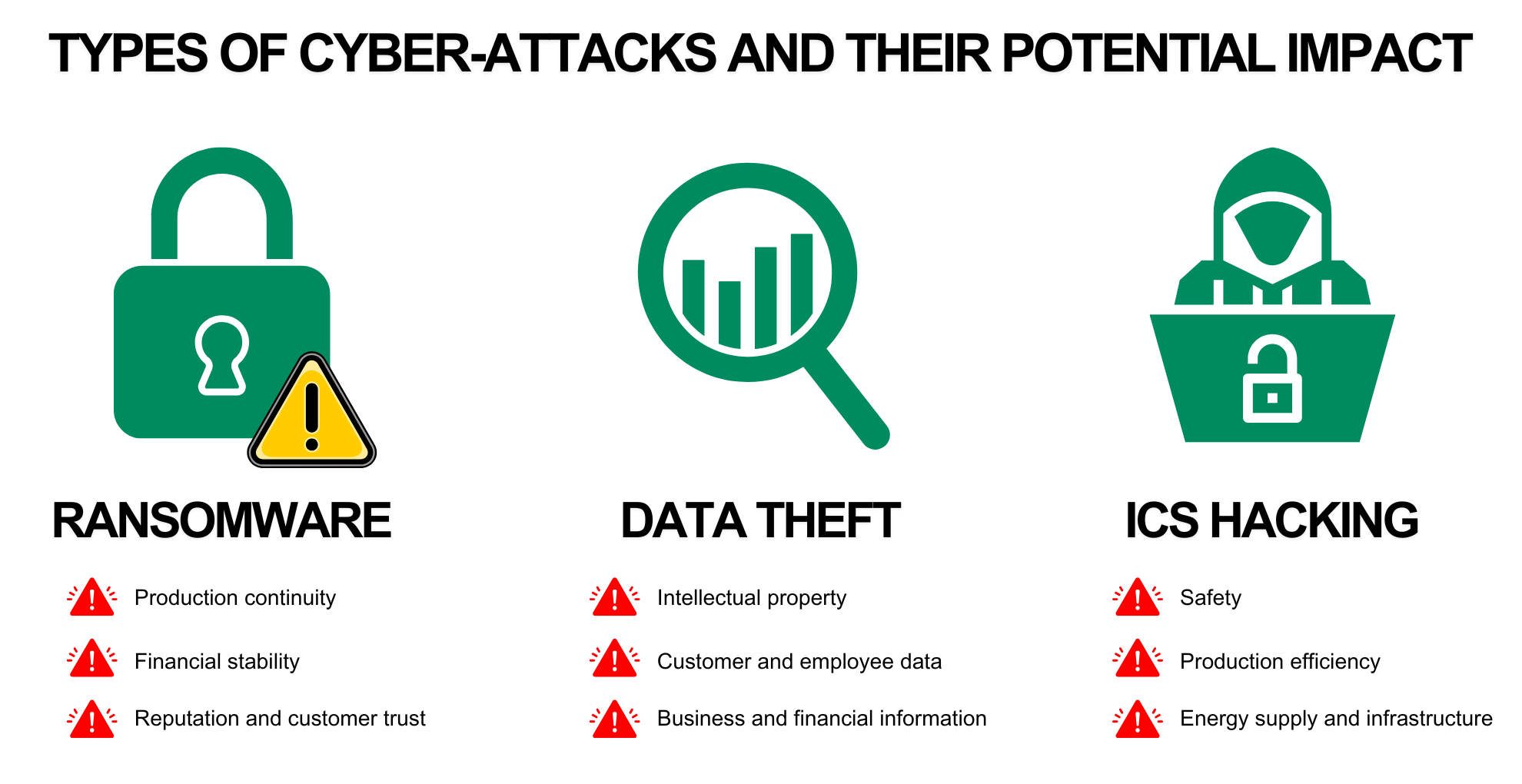

Taking into account that any business today is greatly dependent on numerous IT systems, such areas as protection against business critical data loss and continuous operation of IT systems should be among top priorities when drafting the above mentioned action plans. In the manufacturing industry, in addition to constant monitoring of the most critical points in the IT infrastructure (databases, applications, servers etc.), one should be also able to monitor the production software itself as well as the compliance of the entire production process to certain required parameters (pressure, temperature, weight etc.). I would like to point out that today both IT and production infrastructure can be effectively monitored with the help of various innovative solutions. They, in addition to pure monitoring, also provide an opportunity to analyze operational trends of critical infrastructure points as well as discover and foresee the development of any bottlenecks. Continuous monitoring of the most critical business process points also ensures that You will be notified about and able to deal with any deviances from set performance standards before they paralyze Your main business processes. As a result, you may enhance the competitive advantage of your business. Moreover, with a global picture of your business process performance in your hands, you will be able to align different process steps a lot more accurately and improve business process throughput and performance across the entire Company.

The main rules or guidelines for the development of a BCP or DRP are similar:

Aiming for a higher value-added through business process continuity

I really invite every top or middle level manager to think of the costs critical business process downtimes bring to a Company. These downtimes are often caused by such simple incidents as loss of internet connection or malfunctioning of the production or IT equipment, cash registers or any other business-critical devices. In my opinion, business process continuity should be one of the top management priorities, but not only for the sake of “a tick in the checkbox.” For BCP and DRP to bring the result you may want, both of them must be regularly tested, fine-tuned and supplemented in order to maintain their relevance while your business processes continue to change and develop further. Implementation and maintenance of a business process continuity strategy and mindset in Your Company, in the long run, will enhance not only your competitive advantage but the value- added of your business as well. Seeing that you are highly motivated and working hard to eliminate various internal risks and ensure a continuous flow of goods and services, will increase the value of Your Company in the eyes of both - Your employees and business partners.

Regular analysis and elimination of internal risks and business process bottlenecks is a valuable source for steady business growth and development! Wishing you success!

Garā iela 2, Dreiliņi, Stopiņu novads

Garā iela 2, Dreiliņi, Stopiņu novads