Modern manufacturing companies are increasingly adopting advanced technologies to enhance efficiency, reduce costs, and improve competitiveness. However, the digitalization and automation of production processes bring new challenges, particularly in AI technology integration and cybersecurity. This article explores two key areas that manufacturing companies must focus on.

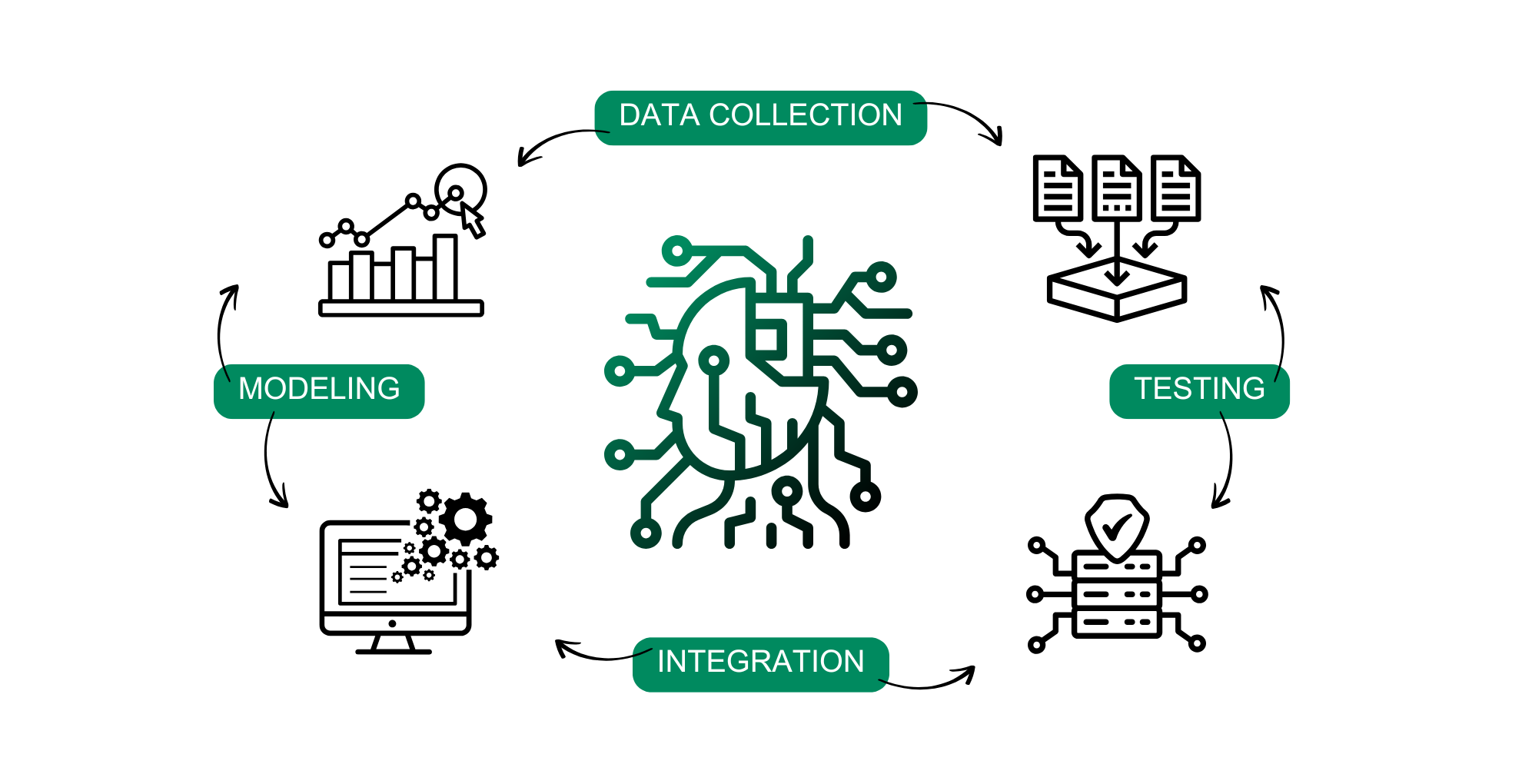

AI Technology Integration: Key Challenges

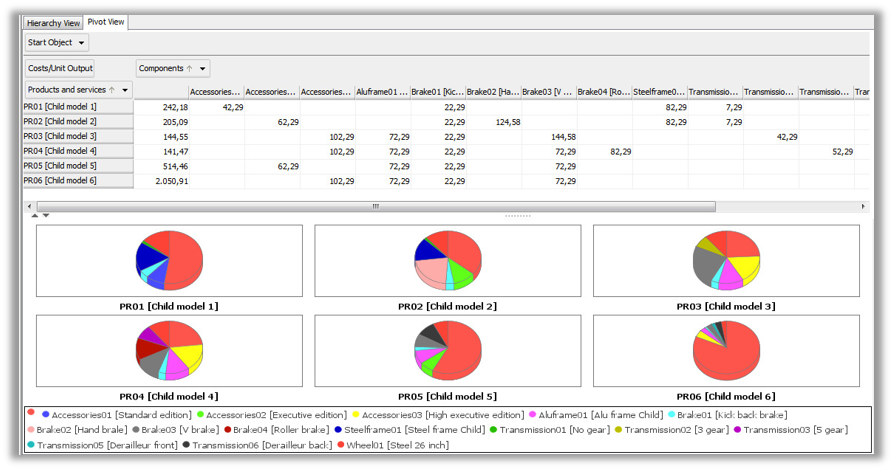

More and more manufacturing companies are implementing artificial intelligence (AI) solutions to optimize production processes, predict equipment failures, and improve quality. However, integrating AI into existing systems is not a straightforward process and presents several challenges:

1. Compatibility of Existing Systems with AI

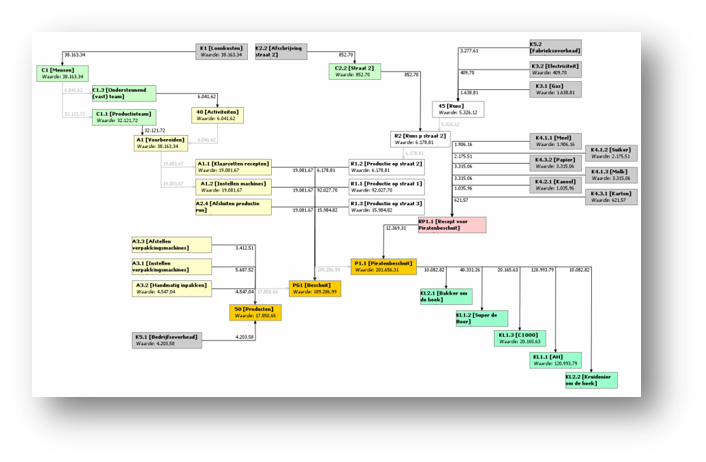

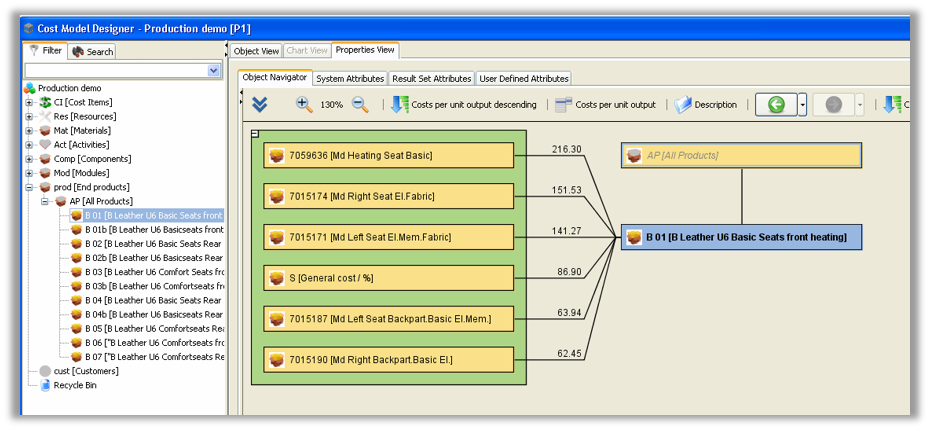

Many manufacturing companies operate legacy ERP, SCADA, and production management systems that were not designed to work with AI solutions. The integration process often requires modernizing the existing IT and OT infrastructure or creating a middleware layer to enable seamless AI-driven data processing.

2. Data Quality and Availability

AI solutions rely on high-quality and well-structured data. In manufacturing environments, data is often scattered across multiple systems and lacks standardization. To successfully implement AI, companies need to establish data standardization and storage strategies to ensure reliability and accuracy.

3. Workforce Readiness

AI adoption requires new skills that existing employees may not possess. Companies must invest in workforce training and establish interdisciplinary teams that bring together manufacturing, IT, and data science specialists to ensure effective AI deployment.

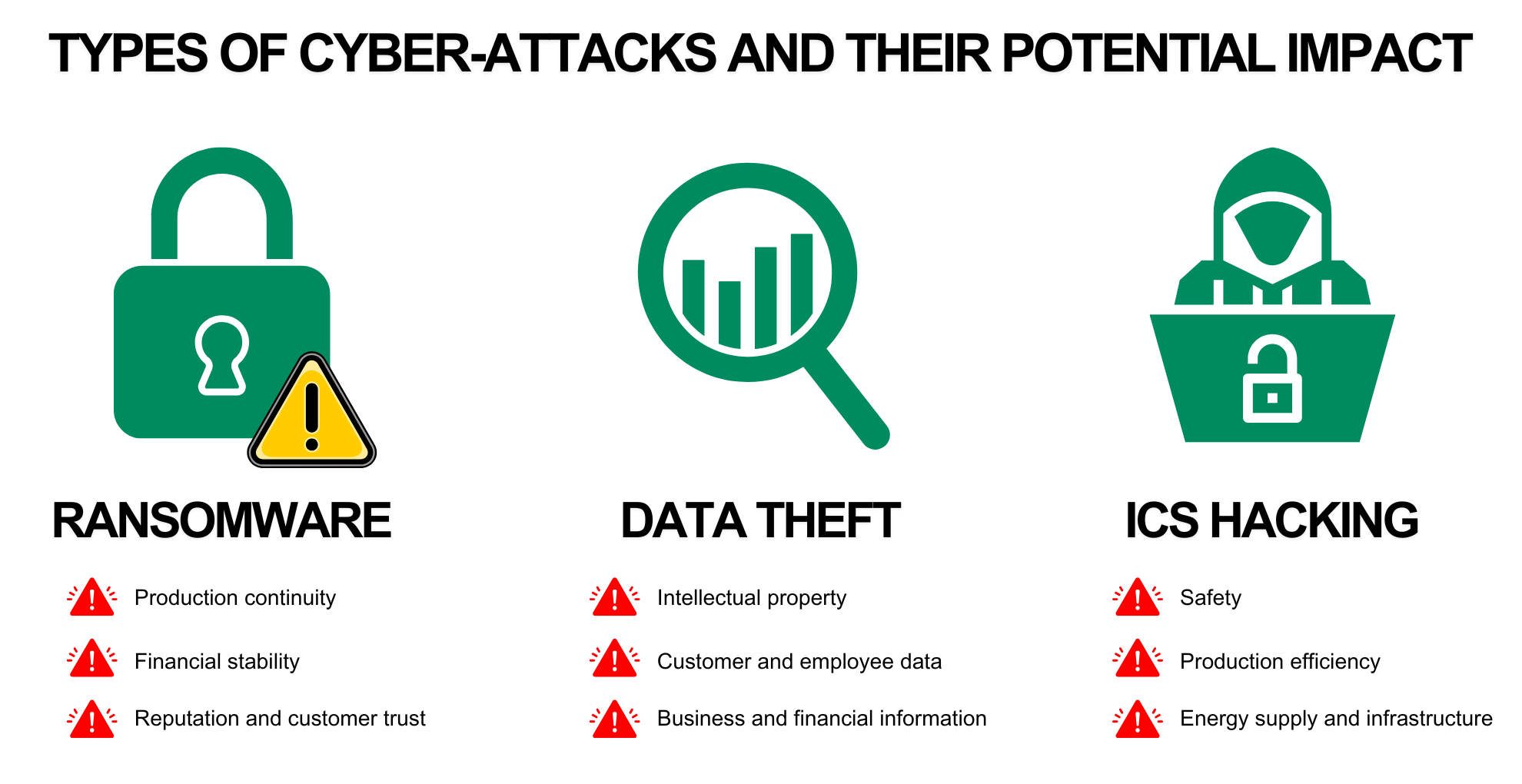

Cybersecurity in the Manufacturing Environment

As digitization increases, cybersecurity has become a critical concern for manufacturing companies. Today, production equipment is more interconnected than ever, which raises the risk of cyber-attacks.

1. Increased Risk of Cyberattacks

Manufacturing companies have become frequent targets of cyberattacks, as disruptions can cause severe financial losses and production downtime. The most common attacks include:

2. Dependence on Third-Party Services

Many manufacturing companies outsource IT and industrial system maintenance, which introduces additional security risks. It is essential to ensure that third-party providers comply with strict cyber-security standards and protocols to mitigate potential vulnerabilities.

3. NIS2 Regulatory Requirements

The European Union is introducing stricter cybersecurity regulations, including the NIS2 directive, which requires manufacturing companies to implement enhanced security measures. Compliance with these regulations demands new cybersecurity strategies and significant investments in IT security.

Conclusion

Technology integration and cybersecurity are two critical areas that manufacturing companies must address to remain competitive and protect their data and production systems. AI implementation can significantly enhance efficiency, but successful integration requires compatible IT infrastructure, high-quality data, and trained personnel. Meanwhile, cybersecurity measures are essential to prevent cyber threats and ensure compliance with industry regulations.

Eddi Ltd. is an experienced partner in Information Technology, Operational Technology, and Facility Management solutions integration, helping manufacturing companies securely and efficiently adopt modern technologies.

If your company is looking for a reliable partner for AI implementation or cybersecurity improvements, contact me and my team today at eddi@eddi.lv

We will ensure that your manufacturing technologies not only work, but also help your business grow.

Garā iela 2, Dreiliņi, Stopiņu novads

Garā iela 2, Dreiliņi, Stopiņu novads